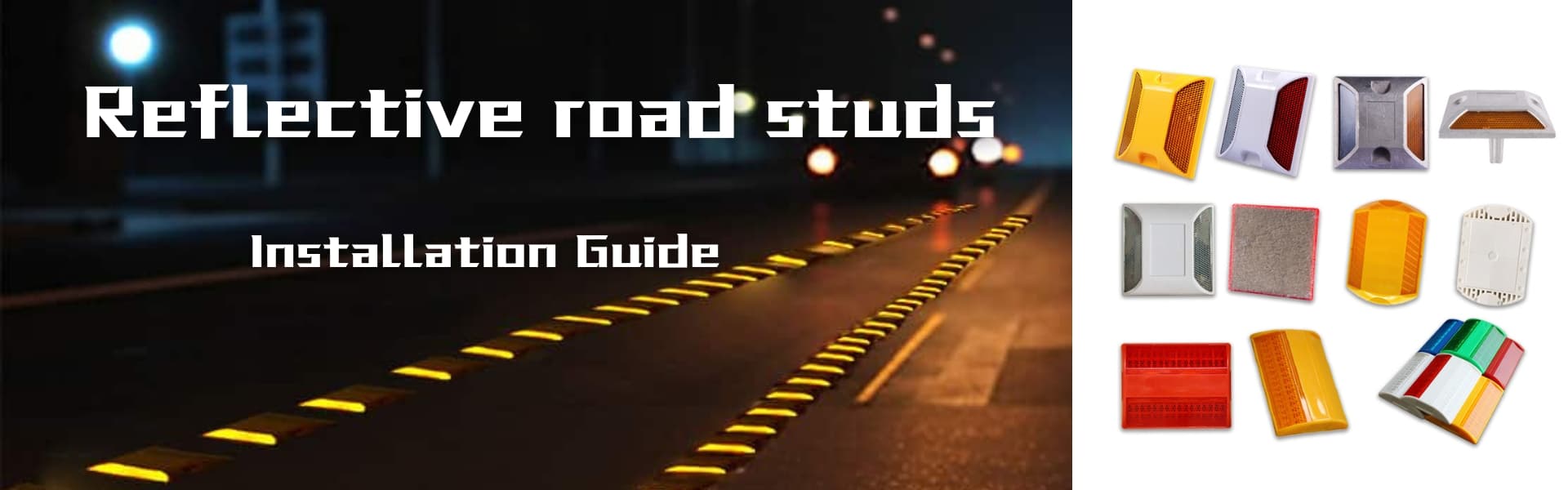

What are reflective road studs?

There are two common road studs: one is solar road studs, and the other is reflective road studs.

Reflective road studs are an important traffic safety facility. They do not need to use any energy. They can emit bright light through light reflection to remind drivers to drive in the lane. Reflective road studs have played a very important role in traffic guidance on various roads, such as highways, urban roads, and many bridges and tunnels. In this article today, we will discuss with you the installation method of reflective road studs to ensure that you can install them correctly and put them into use as soon as possible after receiving the reflective road stud products.

Installation steps of reflective road studs

1. Set up safety isolation.

When you install reflective road studs, safety is the top priority and must not be ignored. Whether installing reflective pavement studs on new roads or roads that have been opened to traffic, make sure that all construction workers are within the safety isolation. If you are working on a road that has been opened to traffic, the ratio of safety personnel to installation personnel should be 1:1. If you are working on a road that has not been opened to traffic, the ratio of safety personnel to installation personnel should be 1:3.

2. Determine the installation location.

According to the road design and engineering requirements, determine the installation position and spacing of the road spikes. You need to keep the installation distance between every two road spikes consistent and make marks.

3. Surface treatment.

Before installing the

reflective pavement studs, you need to grind the road surface where the reflective road spikes are connected. You can use an angle grinder to grind. The surface thickness is about 1~2 mm. Ensure that the road surface is very solid, and then wipe the surface clean with a rag using an acetone solution and wait until it dries. If there is a dent problem, it needs to be repaired with road spike glue until it is flat.

4. Configure road spike glue.

Road spike glue is divided into two types, ab, and needs to be mechanically stirred to be evenly configured. You can prepare a container without water or impurities in it and then stir it correctly according to the proportion. Stir with a whisk in the same direction for about 10 minutes without generating bubbles.

5. Apply glue.

You can use a putty knife to evenly apply the configured glue on the road and the part where the reflective pavement studs are pasted. Be careful not to apply it to the expansion joints of the road surface. The thickness of the coating is about 2 mm. You need to ensure the position is accurate, and then apply a little pressure. If there is too much glue, be sure to clean it up.

6. If it is a cast aluminum footed road stud, make sure that the hole depth is greater than the foot depth of the nail by 25px , the hole diameter is greater than the foot diameter of the nail by 2mm.

7. Inspection

After the reflective road studs are installed, an inspection should be carried out within two hours to ensure that all reflective road studs are not installed upside down, crooked, or pressed.

8. Curing

After the reflective road studs are cured for 4 hours, remove the installation isolation facilities.

Precautions for the installation of reflective road studs

For you, the installation of reflective road studs should not be a very complicated thing, but as a responsible reflective road stud manufacturer, we have the obligation to remind you that there are the following precautions when installing

reflective road markers:1. The climate environment for installing reflective road studs is very important.

It must be carried out in dry weather conditions to avoid rain or slippery road installation, so as not to affect the installation and use of reflective road studs.

2. Choose appropriate installation tools and materials.

According to the road surface installation environment of the reflective road markers, such as concrete pavement or asphalt pavement, choose appropriate adhesives and drilling tools.

3. Do not touch the reflective road studs with your hands.

Avoid getting glue on the reflective road studs to avoid affecting the reflective effect.

4. Ensure the safety of the installation environment and construction workers.

Especially when constructing on roads with heavy traffic, safety isolation measures must be taken. Correct installation of reflective road markers is the basis for them to play their maximum role and is also a necessary measure to extend the service life of reflective road studs. In actual use, reflective road studs are often damaged due to installation problems, and their service life does not meet expectations. Therefore, if you want reflective

road studs to play a long-term and stable role, please be sure to install them according to the correct construction steps to ensure that they can be safely and firmly fixed on the road and guide people in the right direction for travel.