Solar road stud lights, heralding a new era of sustainable road safety, undergo a meticulous production process that blends cutting-edge technology with precision engineering. This article unravels the intricacies of their manufacturing journey, shedding light on the steps that culminate in these beacons of illumination.

Raw Material Selection: The production journey commences with the careful selection of materials. High-quality aluminum or polycarbonate, known for their durability and resistance to environmental factors, are often chosen. The choice of materials ensures the studs can withstand the rigors of varying climates and heavy traffic, promising longevity in operation.

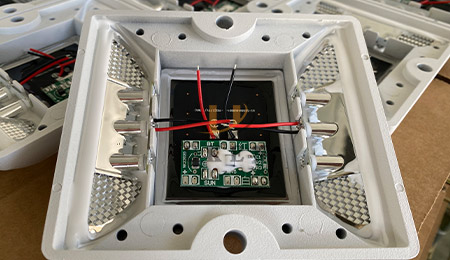

Photovoltaic Cell Integration: At the heart of

solar road studs lie photovoltaic cells, responsible for capturing and converting sunlight into energy. During the production process, these cells are intricately integrated into the design, ensuring optimal exposure to sunlight. This meticulous step is pivotal in guaranteeing the efficiency of the solar road stud lights in harnessing and storing solar energy.

Battery Assembly: Efficient energy storage is fundamental for the uninterrupted operation of solar road studs. The production process involves the assembly of high-capacity batteries that store the energy collected by the photovoltaic cells during daylight hours. These batteries must be durable and reliable, capable of withstanding frequent charge and discharge cycles for extended product life.

LED Light Integration: The integration of LED lights is a critical phase in the production process. The selected LEDs, known for their brightness and energy efficiency, are embedded securely within the design. Smart control systems are often incorporated to adjust light intensity based on real-time traffic conditions, enhancing adaptability and ensuring optimal energy consumption.

Encapsulation and Sealing: To safeguard the internal components from environmental factors such as moisture and dust, the solar-powered road studs undergo encapsulation and sealing processes. This step ensures the longevity and resilience of the studs in the face of adverse weather conditions, making them suitable for installation in various climates.

Quality Control and Testing: Before reaching the end-users, each solar road stud undergoes rigorous quality control and testing. These assessments include functionality checks, water resistance tests, and durability evaluations. Only studs that meet stringent standards are deemed ready for deployment, guaranteeing that each unit delivers reliable performance on the road.

In conclusion, the production process of solar

LED road stud lights is a harmonious blend of material science, technology, and quality assurance. From raw material selection to the integration of advanced components and rigorous testing, every step is meticulously executed to ensure the creation of durable, efficient, and sustainable road safety solutions.