Introduction The production of

solar road stud lights is a fascinating journey that intertwines technology and sustainability to create beacons of safety on our roads. As demand for eco-friendly solutions rises, the meticulous process behind these innovative devices plays a crucial role in reshaping our approach to road safety and visibility.

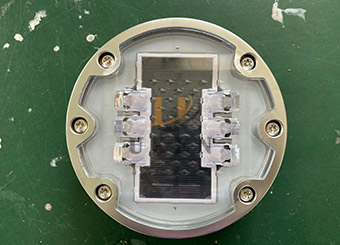

Design and Engineering The production journey begins with the meticulous design and engineering of solar road stud lights. Engineers and designers collaborate to create robust structures that house essential components like solar panels, LED lights, and intelligent controllers. The design phase ensures not only durability but also optimal integration of these components for efficient energy capture and illumination.

Solar Panel Integration The heart of solar road studs lies in their ability to harness solar power for illumination. Solar panels, carefully selected for efficiency, are integrated into the design. These panels capture sunlight during the day, converting it into energy that powers the LED lights during the night. The efficiency of this solar panel integration ensures sustainable and continuous operation, reducing the reliance on conventional power sources.

LED Light Manufacturing The LED lights used in solar-powered road studs undergo a precise manufacturing process. High-efficiency LED bulbs are selected for their luminosity and energy efficiency. These lights are then integrated into the stud’s housing, creating a durable and weather-resistant fixture that ensures optimal visibility in various weather conditions.

Battery and Controller Assembly Assembled solar panels and LED lights are integrated with high-capacity rechargeable batteries and intelligent controllers. These components work in harmony to store the harvested solar energy during the day and regulate its efficient use during the night. The integration of smart controllers allows for dynamic adjustments, optimizing lighting intensity based on environmental conditions.

Quality Assurance and Final Assembly In the final stages, rigorous quality assurance checks are conducted to ensure each cat eye road meets stringent standards for performance, durability, and weather resistance. The finished units then undergo final assembly, bringing together all components into a seamless, functional whole. The result is a solar road stud light ready to be deployed, contributing to safer roads and enhanced visibility.

The intricate production journey of

LED road stud lights showcases the fusion of cutting-edge technology and sustainable practices. From design and engineering to the integration of solar panels, LED lights, and intelligent controllers, each step plays a crucial role in creating a reliable, eco-friendly solution for road safety and visibility.